Maximizing the potential of data

The information on the website is updated in good faith but may contain errors and is subject to change without notice. The use of such content is entirely at the user’s own risk. More info

Guiding the future through data

In today's business landscape, several Italian companies are adopting an innovative operational approach. The implementation of advanced tools and the optimization of processes are fundamental pillars for business management.

However, this evolution goes far beyond the simple adoption of technologies. The true focus lies in the conscious and strategic use of data generated by these technologies, a crucial aspect for both manufacturing and service-oriented businesses.

In a time where the business routine is permeated by advanced technological solutions, the perspective shifts towards deepening the knowledge derived from data.

It's not just about collecting information, but understanding deeply how to leverage it to gain a significant advantage. This challenge is not confined to specific sectors; intelligent data management has become a cross-cutting necessity.

The value of data extends beyond operational optimization. Today, the conscious management of these resources is the key to guiding strategic business decisions.

In a world where innovation is closely tied to a deep understanding of data, the ability to use them smartly becomes the focal point for sustainable business growth.

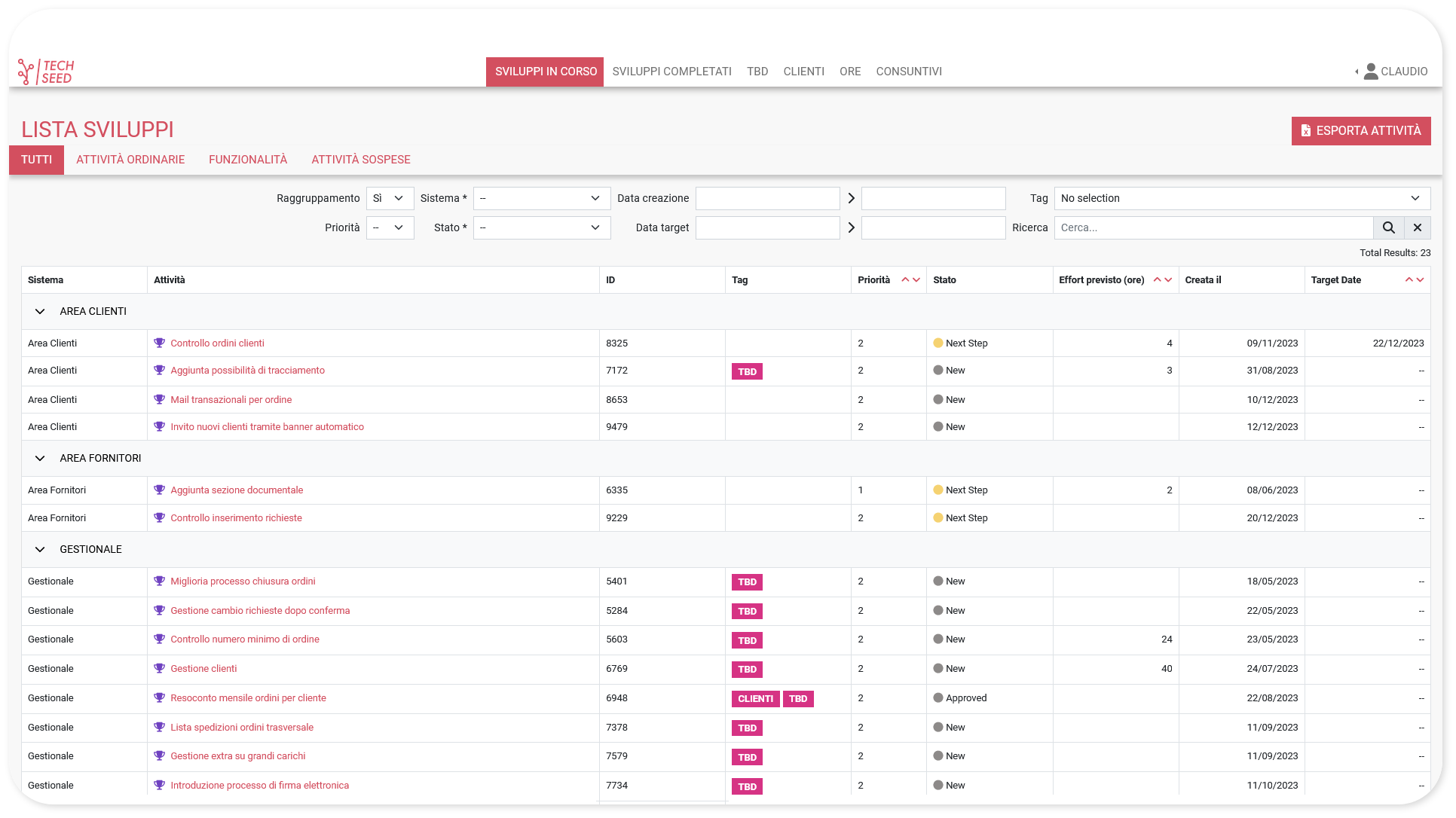

Fully Harnessing Data with Our Services

We have developed innovative projects for our clients, helping them maximize the strategic use of their data.

The following possibilities provide just a glimpse of what is achievable with the right management and analysis of data.

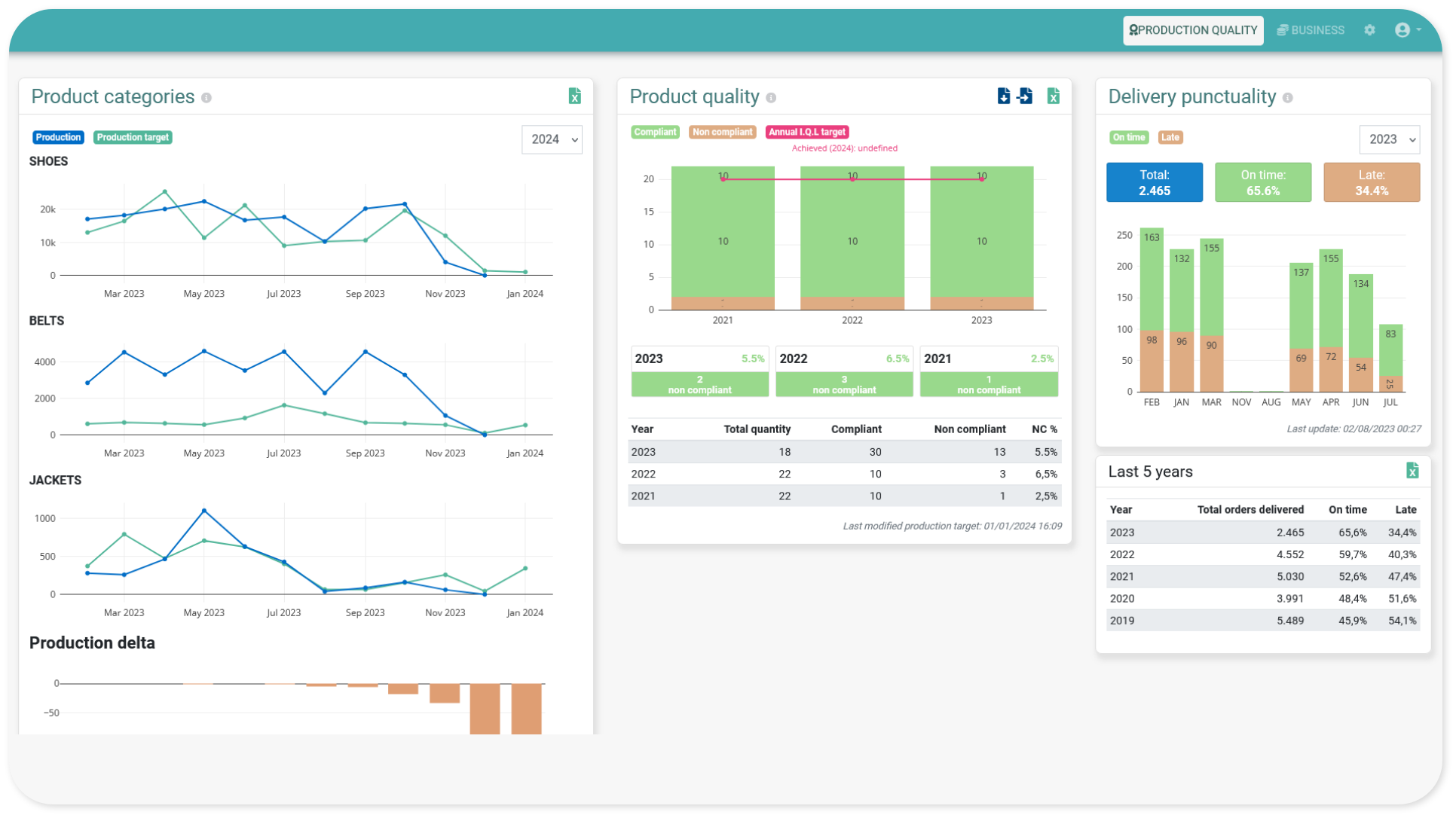

Dashboard

Quality control and product innovation

KPI

Performance evaluation

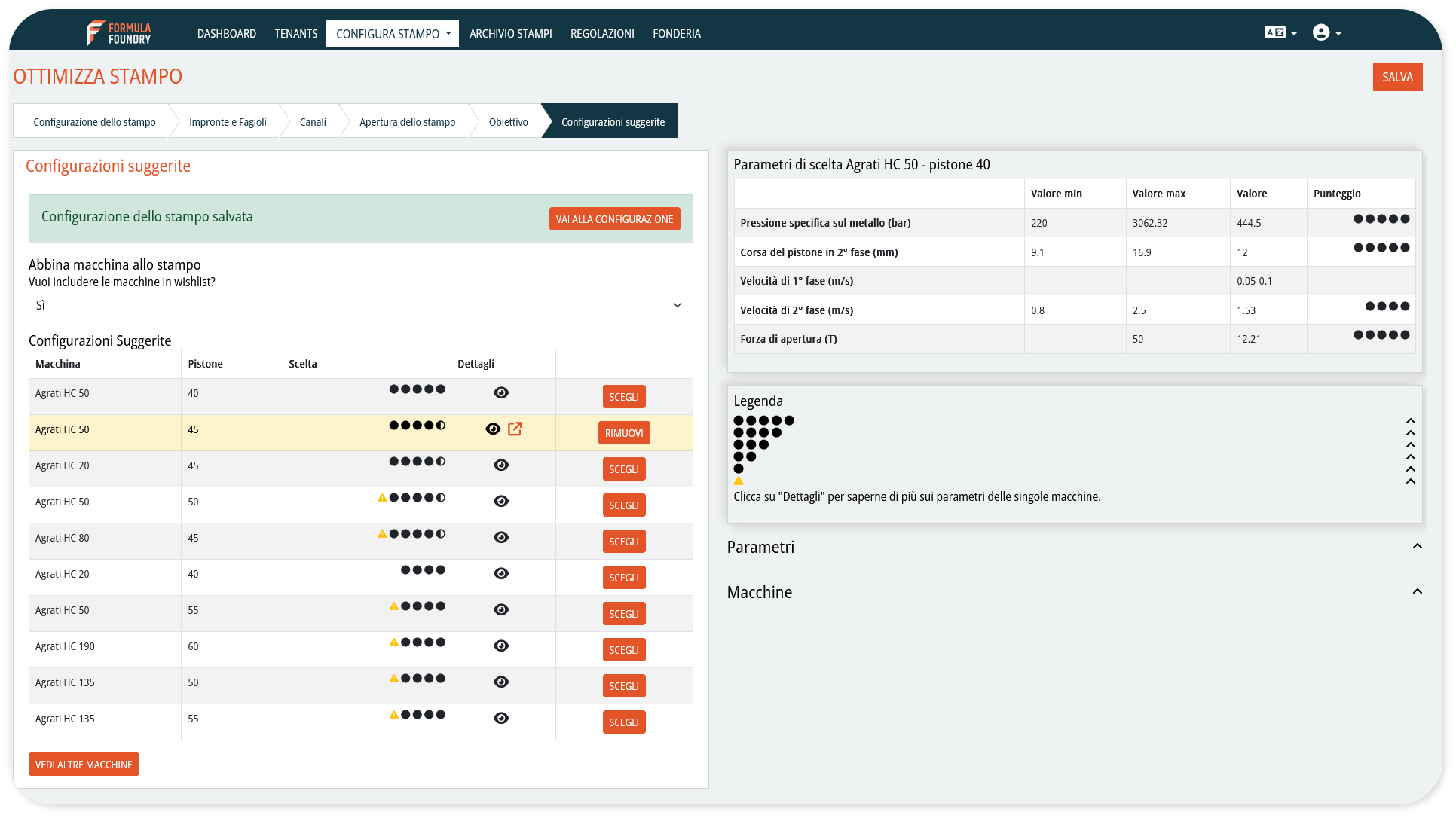

Machines 4.0

Performance, quality, efficiency